One of the main activities of the BK Technic company is the complex supply of production lines, intended mainly for the automotive industry. Specifically, it involves development, designing, electro-designing, production, assembly, programming of control systems, visualization of processes, programming of camera and measuring systems, programming of robots, and we also provide all warranty and post-warranty service. From the initial phase of the project, we work with customers on the most suitable possible solution.

We are a direct manufacturer of application technology, including individual application units such as piston pumps, gear pumps, piston dispensers, application guns and many others. At the same time, we produce complete electrical control including software, visualization, robot programming, camera and measurement systems.

Thanks to our team of experienced designers, electrical designers, PLC programmers and, last but not least, a modern CNC tool shop, we produce single-purpose machines for various industries and uses. Above all, it involves parts handling, assembly, gluing, sealing, lubrication, pressing, screwing, measuring, checking, tests and many others.

We have been dealing with programming of ABB and KUKA robots for a long time. We have already delivered dozens of robotic workplaces to our customers.

We deal with the complete process of industrial automation. Specifically, it involves the design of electrical systems using the E-plan program, production and assembly of electrical switchboards, development and programming of control systems, visualization, data collection, programming of camera and measurement systems.

BK Technic has a team of experienced designers and electrical designers. We create all 3D data in SolidWorks. We design electrical systems in the E-plan program.

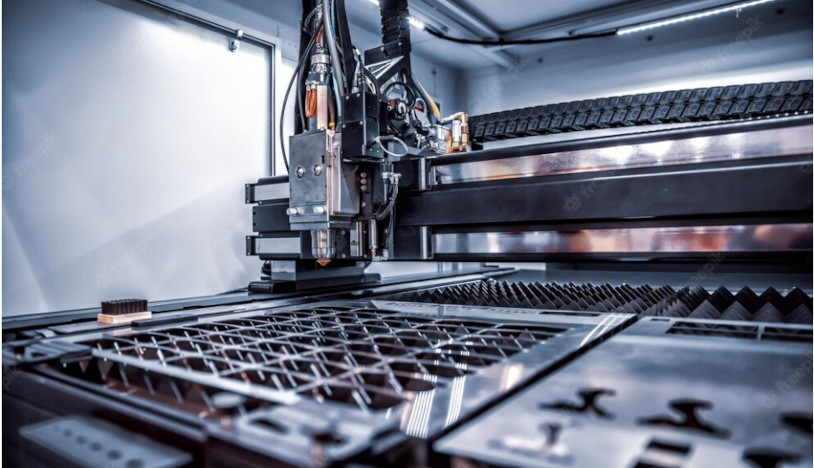

The BK Technic company has a modern equipped CNC tool shop. Thanks to the direct connection of construction with CNC production, we achieve fast, accurate and, above all, highly efficient production of exact machine parts. We use the HSMWorks software for production, it is a CAM system fully integrated into the SolidWorks CAD system.

BK Technic has a modern 50W fiber laser. We mark and engrave stainless steel, steel, hardened metals, brass, copper, gold, aluminum and titanium. Advantages of laser marking: top quality, accuracy and speed, permanence (cannot be erased), non-contact processing, use for almost any material. Advantages of laser engraving: indelibility, permanence, precision, detailed processing, durability, non-contact processing.

The company BK Technic s.r.o. provides comprehensive and flexible warranty and post-warranty service for all implementations.

Do you need advice? Get in touch with us. We are here for you!

© BK Technic s.r.o. 2022 | Made by: ELIS web | WOIT s.r.o.